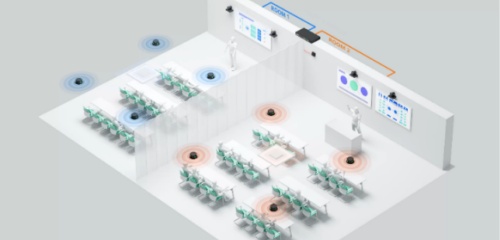

Yealink's unified management platform empowers manufacturing enterprises with centralized, multi-site control of meeting spaces across plants, offices, and headquarters.

From Cross-Plant Communication to Global Meetings

AI-Driven Comprehensive Collaboration Solutions for Manufacturing

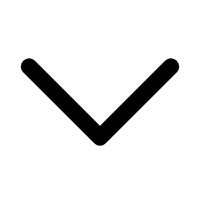

"Our IT team has tested and implemented modern and reliable video conferencing systems that provide a comparable virtual communication experience, almost like being there in person.”

"All Yealink devices are easy to understand and use, stable, and can be fully managed and monitored by IT."

Smart Operations, Connected Factories.

From offices and meeting rooms to bustling factory floors our AI-powered clarity enables seamless hybrid collaboration and faster decision-making—cutting through noisy industrial environments so teams can work efficiently from anywhere.

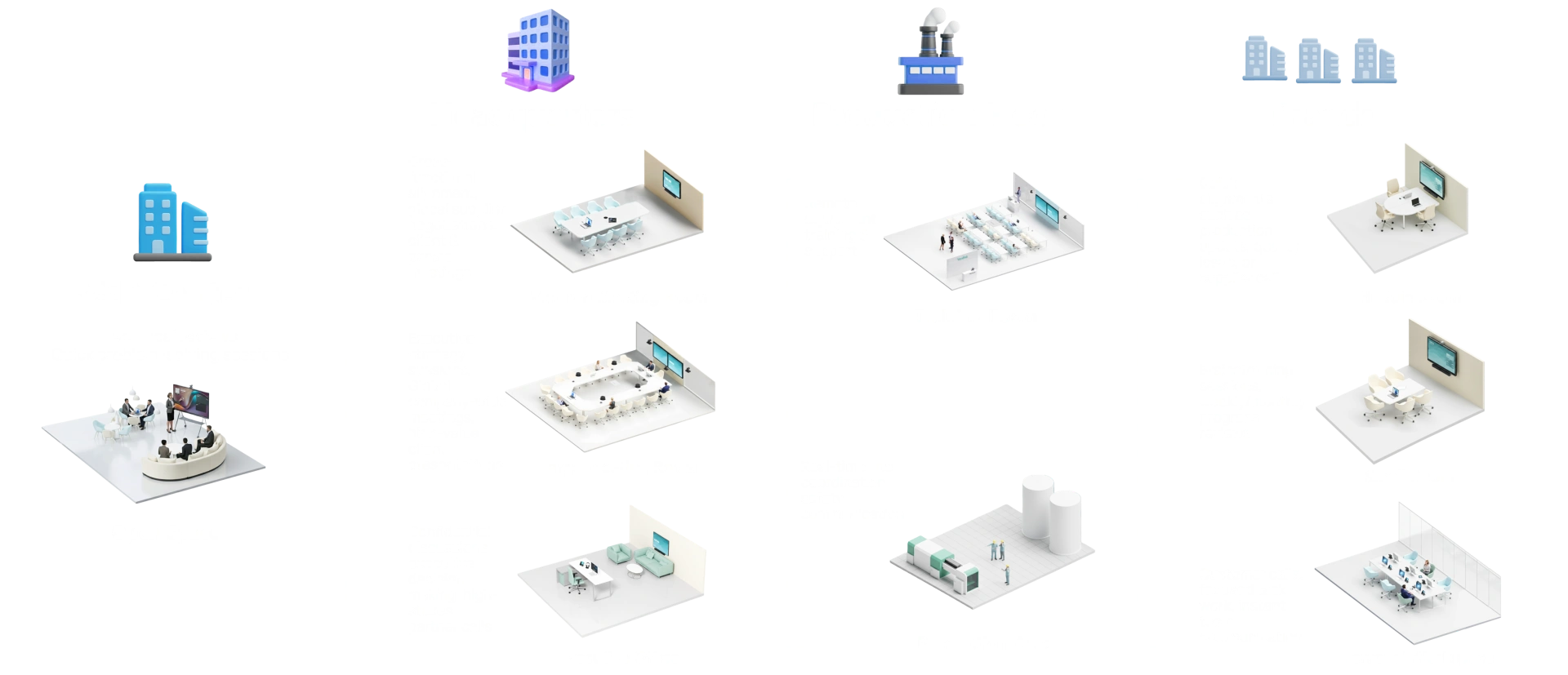

A25

A25 CTP25

CTP25 Meeting Display 65

Meeting Display 65

A40

A40 CTP25

CTP25 Meeting Display 65

Meeting Display 65 PA20

PA20 SmartVision 40

SmartVision 40 McoreKit

McoreKit Meeting Display 65

Meeting Display 65

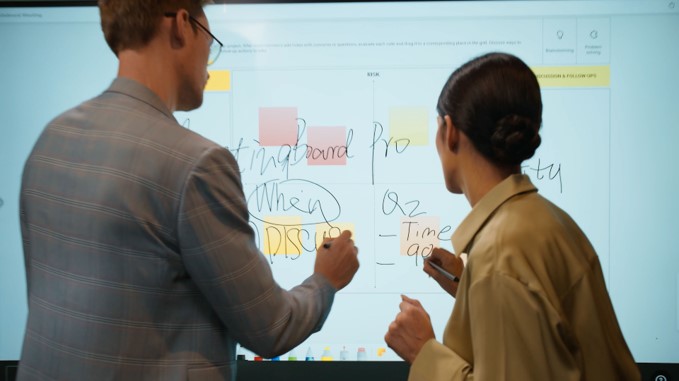

_board.webp)

Meetingboard Pro

Meetingboard Pro Mcore-OPS-T

Mcore-OPS-T CTP25

CTP25

MVC S98

MVC S98 CM50

CM50

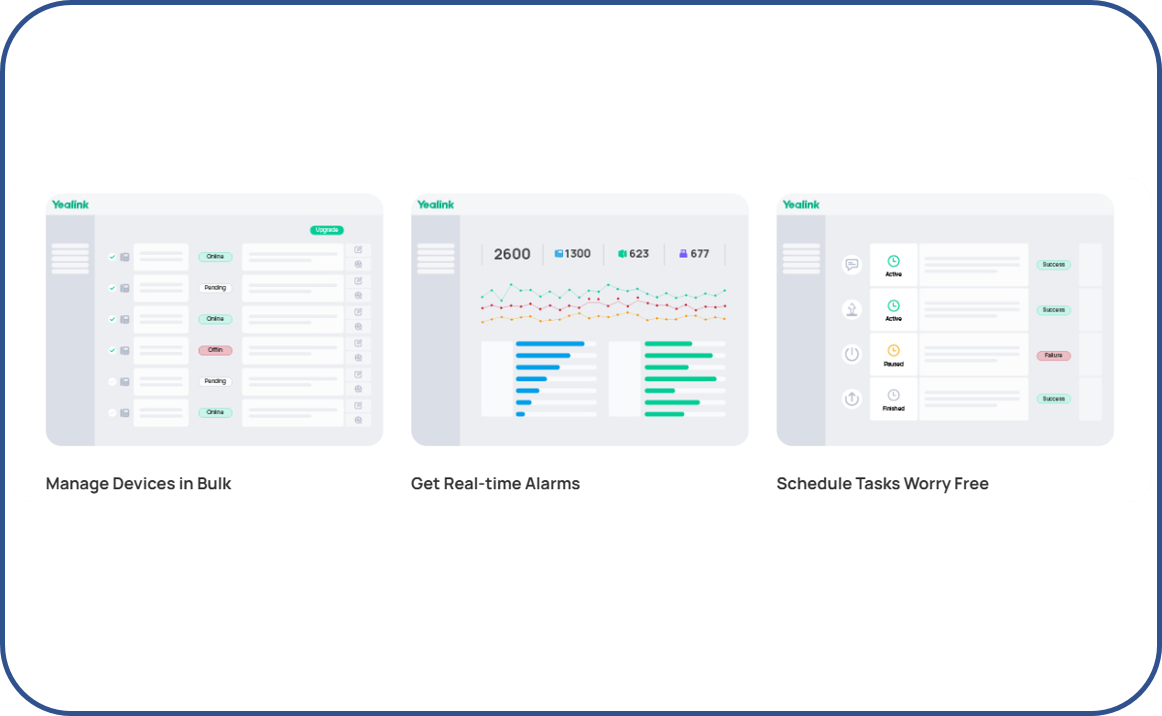

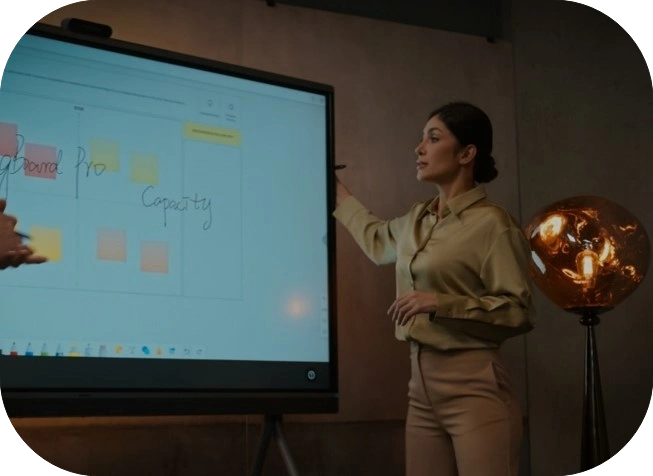

Reception

Reception Open Office

Open Office Manager Office

Manager Office

General Production Areas

General Production Areas Heavy Machinery Areas

Heavy Machinery Areas Temporary Workshop

Temporary Workshop Wide-Area Mobile Operations

Wide-Area Mobile Operations